Of course, we all wish every day was a powder day here on the mountain. However, that’s not how Mother Nature always works. At Stratton, our average annual snowfall is 180 inches. We have over 1,000 snowguns that cover 95% of our terrain to help us keep the mountain fresh with snow and allow us to open more terrain as early as possible and keep it open as late as possible. That’s why when you visit you might see our tall skinny tower guns blowing misty clouds of snow into giant fluffy piles we like to call ‘whales’.

Our snowmaking team works hard all season long to ensure we are making as much snow as we can, as efficiently as we can. We don’t fire up our snow guns unless we know conditions are optimal and the snow we blow is going to last. There are a lot more factors that play into snowmaking than just cold air temperatures, and all of them inform why we make some of the decisions we do.

“I spend a lot of time looking into the forecast of temperatures, wind and other factors. Many times it’s best to wait for ideal temperatures rather than take advantage of barely freezing and less-than-good snowmaking temps,” said Kevin Booth, Stratton Snowmaking Manager.

The Scientific Process

Snowmaking in its simplest form is turning water into snow. The most obvious necessity in this process is a cold ambient (air) temperature. However, even if it’s below 32 degrees outside, humidity plays a key roll. The combination of temperature and humidity gives you the wet bulb, which determines snow quality and energy efficiency. The lower the humidity, the lower the wet bulb temperature.

Snowmaking is a heat exchange process. Heat is removed from snowmaking water by evaporative and convective cooling and released into the surrounding environment. As some of the water evaporates from the surface of the droplet, a small amount of heat is removed from the droplet itself. The droplet needs to cool to at least 32 degrees during the freezing process. When the air is humid, there is already a lot of moisture in the air. The heat is less readily absorbed into the air and is unable to evaporate from the droplet, thus the droplet cannot freeze or stay frozen.

Because humidity is such an important factor, snowmakers must pay attention to the wet-bulb temperature, which is the air temperature in relation to humidity. The lower the wet-bulb temperature, the dryer the snow. A wet-bulb temperature of 27 is required to make snow, but it will be very wet, poor-quality snow. A wet-bulb temp of under 20 is generally accepted as optimal. Here at Stratton, our snowmaking control system automatically converts the dry ambient temperature into the wet-bulb temperature in order to help inform our snowmaking team.

The wind is another major factor in snowmaking decisions. The wind on the mountain blows snow in all sorts of directions and can change at seemingly any moment some days. Snowmakers have to keep a close watch on the forecasted winds, aim the guns strategically and continually move them as the wind changes in order to get the snow to go where they want it. When it comes to snowmaking, the less wind the better because snowmakers can control where the snow is piling up.

Manmade vs Mother Nature

Natural snow and man-made snow have a few key differences. Natural snow is lighter, has a lower water content (6%-12%) and has a crystalline mass with those beautiful unique patterns we all know and love. Man-made snow is heavier, has a higher water content (20%-50%) and has a crystalized ball shape that is 200-800 microns small. For reference, a micron is .001 millimeters.

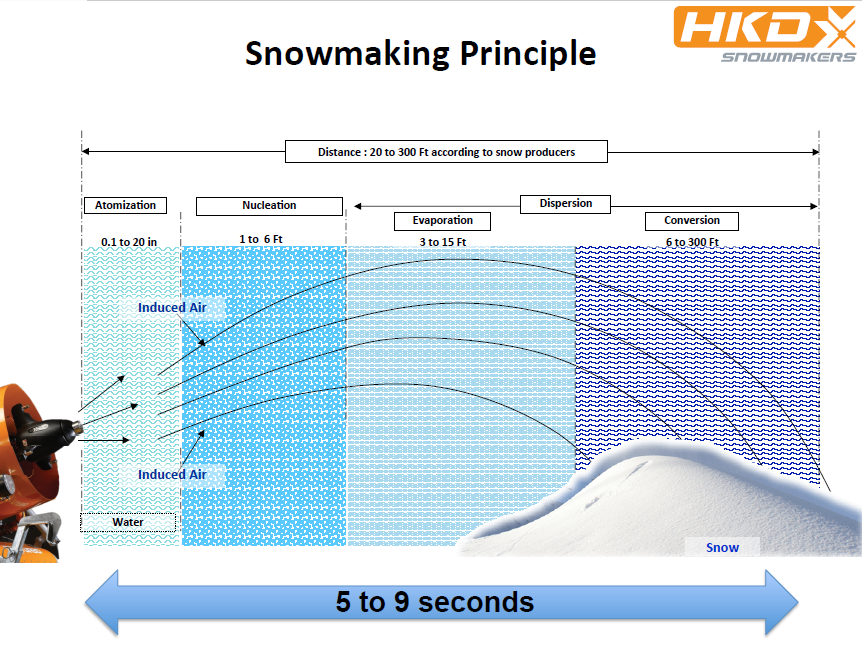

One of the most important differences between the two is that natural snow forms from the inside out whereas man-made snow freezes from the outside in. In the natural environment, microscopic dust particles are usually present in the atmosphere. These particles provide a site for small ice crystals to form and grow while they fall over a fairly long period of time, often minutes. Snowmaking mimics this process, only closer to the ground where the water droplets have just seconds to form ice crystals. Snowguns create external nucleation sites by colliding air at a high velocity with larger droplets of water. These tiny droplets cool much faster than larger droplets, and the size of the droplet has a huge impact on its nucleation temperature, the temperature at which freezing occurs.

“At Stratton we utilize all three technologies of snowguns in order to cover the mountain effectively under different conditions,” said Booth. The guns that we use the most are from HKD snowmakers and are in the ‘Low E’ family. These are the most energy-efficient, they work best in a wide temperature range, are fixed on the side of most of our trails and make great quality snow. The second style of gun is the fan gun. We use these in wide areas such as base areas. These guns make a large quantity of snow but need to have an electrical plug-in on the side of the trail. The third option is a standard air water gun. This kind of technology is older but works best in marginal snowmaking conditions. This is our least-preferred technology and least efficient, but needed on some parts of the mountain.

There’s Something in the Water

“Stratton has the advantage of having a big and reliable water source,” said Booth. “Our snowmaking water comes from two storage ponds including a 150 million gallon pond on Kendall Farm Road and another in the center of the golf course. Because we have these ponds we have not had to adjust any snowmaking plans due to a lack of water.”

We would love to be constantly blowing fresh snow every day. However, efficient snowmaking requires the correct combination of conditions including temperature, humidity, wind, nucleation and droplet size. It uses water and energy so we try our best to consider all of these factors and make strategic decisions about when and where to make snow. With an average of 1,250 snowmaking hours and 1,900 acres of snow one foot deep per season, based on the past 10 years, it’s no secret that our snowmaking team is great at what they do. At the end of the day, our snowmakers are always striving to make skiing and riding here at Stratton as white as possible, and we couldn’t do it without them.

A big shoutout to HKD Snowmakers for sharing some knowledge with us, and keeping our mountain white!